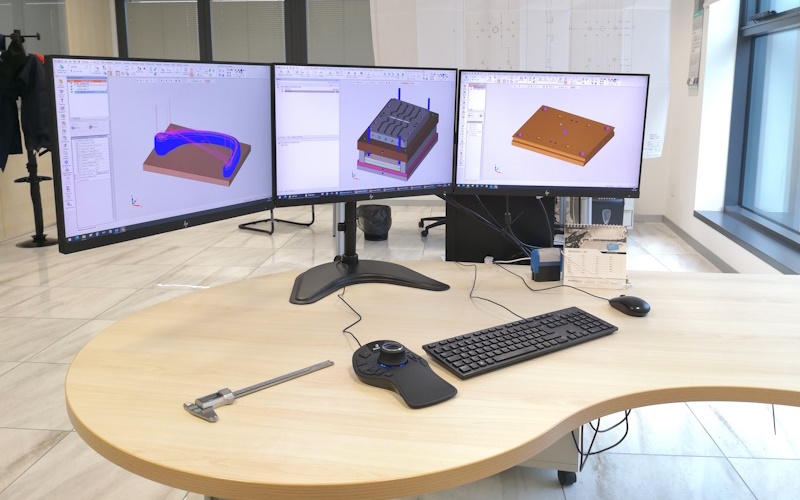

Technical Department

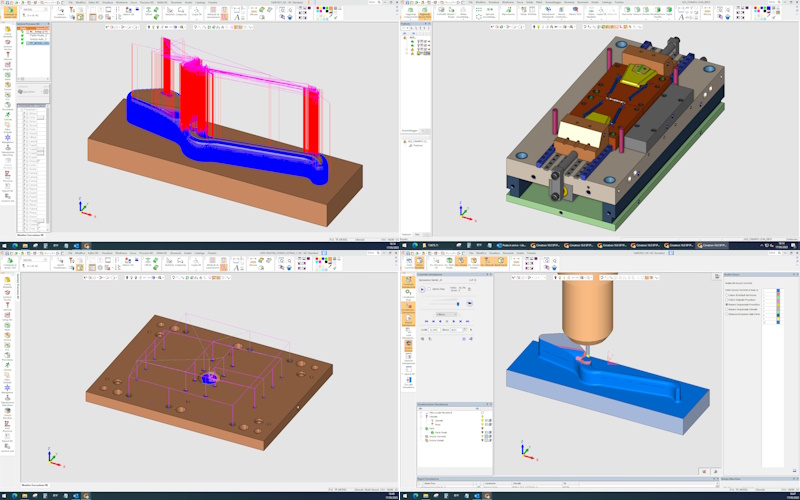

Thanks to the expertise of our qualified technicians, our design department can follow step by step the design of individual components or complete parts. We offer advice on projects and materials to be used, with the possibility of creating prototypes with 3D printing, Moldflow analysis, possible study for the reduction of the component weight, maintaining the mechanical characteristics required by the project in order to reduce costs and the environmental impact of parts and components.

A project can start from a customer’s simple idea and it can turn into the desired product thanks to our know-how. The strong connection between our design office and workshop guarantees very high quality and ensures a careful evaluation of the processing stages to design the mould in the best possible way, thus providing premium quality and durability of all moulds produced.

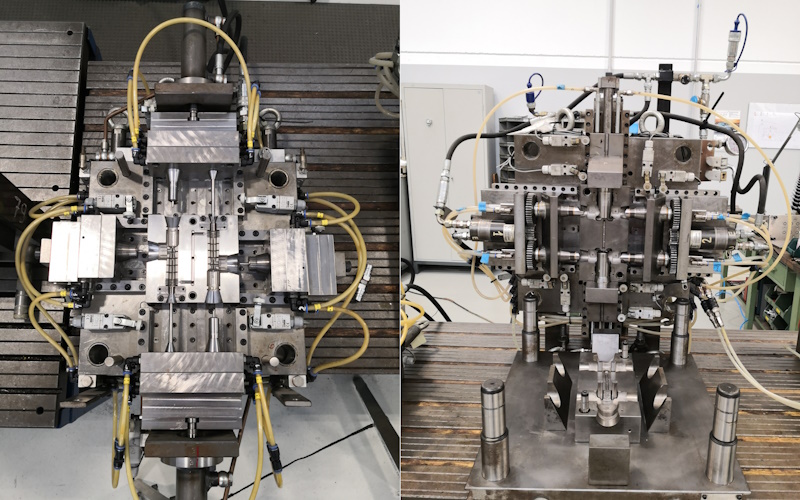

Mould construction department

We are equipped with EDM and CNC machining centres with CAD-CAM programming. In addition, thanks to our internal workshop, we are able to carry out scheduled maintenance on the moulds to ensure high production efficiency, verifying components at risk of wear and thus reducing downtime. Our experience allows us to build moulds characterized by high precision couplings, reducing to a minimum or eliminating stamping burrs even with more difficult technopolymers, avoiding post-injection re-processing.